With vaping, better performance generally comes with increased complexity, and nowhere is this more obvious than with rebuildable atomizers. Vapers enthusiastically recommend rebuildable dripping atomizers (RDAs, for short) to fellow vapers. But when you first pick one up, the unanimous response is a “what the hell am I supposed to do with this thing?”

You may feel out of your depth the first time you see a mod. The voltage, wattage and ohm-readings all crowding the mod's display screen can definitely feel overwhelming, but your first attempt at setting up an RDA will take you to a new level of bewilderment. So if you’re in this situation – and we’ve all been there – it isn’t as scary as it may look. It might not feel like it, but you’ll be confidently building your own coils in no time.

All you need is an introduction to RDAs, how they’re laid out and how to build your first RDA coil.

What is an RDA? What About an RTA?

Although we’ve covered this previously, it’s a good idea to go over the basics again here. A rebuildable dripping atomizer (RDA) is a bare-bones style of e-cig atomizer. They feature a coil and wick but no tank to hold e-juice. Instead, you drip smaller amounts of e-liquid directly onto the coil and wick. Then you vape until the wick starts to dry out before dripping again. They’re “rebuildable” because instead of screwing in a pre-wrapped, self-contained coil, you wrap your own coil and attach it to the atomizer.

RTA stands for “rebuildable tank atomizer.” These are basically the same as RDAs except they do have a tank. This means you get the performance without the constant dripping. This provides a nice balance between the improved performance of a rebuildable atomizer and the convenience of the more common tank systems. In practice, the structure of an RTA is basically a mini RDA surrounded by a tank, with small holes for juice to feed up into the wicks.

Under the Top Cap: RDA Decks Explained

The first step to not being terrified of RDAs is understanding their layout and how they work. The general structure of an RDA consists of a top cap and drip tip covering a deck. The top cap is simply the outer cover of the RDA, and the drip tip is really a mouthpiece for inhaling through.

The deck is where the action happens. This is the part that’s confusing as a newcomer to RDAs, but the confusion is really because there seems to be so little there. Decks generally consist of a few posts with holes through the center and little else, with a small lip around the outer edge and no indication whatsoever of what you should actually do.

The details vary depending on your device, though, so here are the most common layouts you’ll encounter:

Three-Post RDAs

Three-post RDAs are the most basic style and the simplest ones to understand. These have one post in the center – the “positive” post – and two on the outer edges of the deck – the “negative” posts. The positive and negative posts are used to connect up your coil. As the names suggest, they connect your coil up to the positive and negative ends of the circuit. In other words, you need to connect the positive to at least one negative post to complete the circuit.

Most modern RDAs have holes directly through the post itself. These are opened up by unscrewing a screw in the top of the post. Previously, you’d have to trap the end of your wire under the screw-head at the top of the post, but nowadays you simply insert it through the hole in the center and use the screw at the top of the post to tighten it down. Once you’ve done this with both of the legs of your coil, you’ve completed the circuit and the coil will function. It’s best to trim the “legs” of the coil down so they sit as flush to the posts as possible, though.

These RDAs have three posts so you can connect up two coils more comfortably. By allowing the two coils to share the center (positive) post, you’re left with one negative post per coil. This gives you more space and makes it easier to connect everything up without developing a short.

Four-Post (Split Center Post) RDAs

The most common way in which the three-post design is modified is by splitting the center post into two. These are still both positive posts, so they both raise up from the same spot in the center of the RDA’s deck, but they split out a little further up, so they have two post-holes a comfortable distance from each other.

The benefit of this is that it makes it even easier to connect up multiple coils, because the positive ends don’t have to share the same post-hole. This means your two coils can be completely separate from each other, and generally makes the building process easier. For this reason, the majority of RDAs released today will either have this layout or the one described in the next section.

Two-Post (Velocity-Style) RDAs

Going to two post designs after discussing three and four post ones might seem unexpected, but arguably the biggest improvement to the layout of RDAs in recent years came from a device called the Velocity. Instead of having three or four posts, this RDA put the positive post off to one side and left the negative post on the other, but it took the key step of having two holes in each post, one higher up than the other.

This offers the same benefits when it comes to connecting up multi-coil builds, since you have one post hole for each leg on a two-coil build, but makes the whole layout more spacious without affecting ease of use. The screws for the post-holes (or at least for one set of them) are moved to the side of the posts, but the operation is effectively identical.

This layout is no longer confined to the Velocity RDA, with many other devices taking the same layout since it’s release, such as the GeekVape Tsunami.

It’s worth noting that if you went back into vaping history, you’d find a lot more two-post RDAs, but these aren’t Velocity-style offerings. Instead, the two posts were a positive and negative post only capable of holding a single wire-end (and usually in the trap-under-screw-head style), and the devices were very basic. You won’t find anything like this these days – unless you pick up an old IGO-L from someone – but it’s worth mentioning for completeness anyway.

Postless Decks

There are quite a few other unique designs for RDAs (discussed on this reddit thread). However, the most common alternative layout you’ll find is a postless deck.

This may sound outlandish, but really it’s more similar to ordinary decks than you might imagine. The posts aren’t really what’s important; it’s the holes for you to connect your coil-legs up to. For postless decks, there are holes for the positive and negative ends in the same way. The difference is that these holes just go directly down into the deck instead of being drilled through erect posts. They have screws around the edge of the deck to allow you to open up the holes and trap the wire in the same way as posts do.

Juice Wells, Airflow Layouts and Other Features

Before we leave the design elements of RDAs aside and focus on how you build a coil, it’s worth mentioning the other key features you might find on an RDA. Really they’re all quite similar, but small changes can make a big difference to performance and ease of use.

Juice Wells Explained

The simplest additional feature for an RDA is the size of the juice well. The deck is surrounded by a raised lip. This is designed to hold a small amount of e-liquid so you don’t have to “drip” quite as often. This is usually advertised by depth (e.g. “a 6 mm juice well”), and in general a deeper juice well is preferable.

RDA Airflow Designs

One of the other main things you’ll see advertised about RDAs is the airflow system used. These can vary quite a lot – from simple slots in the side of the top cap to more complicated systems – but the goal is always the same. The aim is to provide as much control over airflow as possible without causing too much leaking. Some leaking is hard to avoid, but obviously it’s not ideal, and manufacturers tend to do as much as they can to minimize it.

Air going directly across the coil from underneath straight up to the mouthpiece offers some of the best performance. The problem is that accomplishing this without causing leaking issues is a challenge. This is why some airflow systems are a little complex. Getting the air to hit the coils at an opportune angle often opens you up to excessive leaking, so manufacturers have to be inventive to solve the problem. Some airflow systems draw in air from the top and channel them down so the still hit the coils from underneath. Other systems use a swirling, vortex-like airflow to improve performance without the need for an under-coil layout.

Choosing between these isn’t especially easy, and personal preference has a big part to play in your choice. You should be able to see the potential upsides and downsides of different layouts based on what you've learned. However, you won’t get an idea of what you personally like until you try a few options out. It must be added that most RDAs are much better-suited to wide open airflows and direct-to-lung hits. However, you can usually close the airflow down enough for a mouth-to-lung vape if you prefer. There’s more info on inhalation styles here.

Why Post Hole Size Matters

Another key design feature relevant to RDAs is just how big the holes in the posts (or deck) actually are. This is primarily important because the wire you use for building differs in size, with lower AWG numbers meaning a thicker wire. Post hole size is especially important if you’re hoping to use other wire types such as twisted wire (where two strands are twisted together before being made into a coil) or Clapton wire (where a wire is wound around a central core, like a guitar string). In general, most modern RDAs will be able to accommodate these wire types. That said, due to their design, Velocity-style two-post RDAs often have the biggest post holes.

Insulators, Drip Tips and More

Other RDA features are less crucial but still worth considering if you’re shopping for an RDA. The posts have to carry a lot of current, so good insulation is essential. This is ordinarily accomplished with PEEK insulators, which have great heat-resistance and can cope with sub ohm vaping.

Drip tips used to all be fairly narrow, but now many devices come with “wide-bore” drip tips. These have larger openings to improve airflow. If you’re looking for a direct-to-lung vape and want big clouds, wide-bore drip tips are a great feature for an RDA. However, they do reduce flavor compared to thinner tips.

This really just scratches the surface of the different RDA features you might encounter. But it should give you an idea of what you can expect if you’re shopping for an RDA.

The Beginners’ RDA Building Guide

So now you’ve gotten to grips with the parts of an RDA and have a basic idea of what to look out for if you’re planning on buying one, the only issue remaining is the big one: what do you do with it when you have one?

Thankfully, despite how scary it may seem when you’re first trying to build your own coil, RDAs are straightforward enough once you’ve gotten the basics down. After mastering a basic coil build, you’ll be ready to head out into the big wide world of different coil styles and arrangements, giving you more control over the type of vape you get than you’d have thought possible.

What You Need to Build a Coil

Before you get started building a coil, there are a few things you’ll need:

- Resistance wire (Kanthal, nickel, stainless steel or titanium wire). The most important thing you need to build a coil is the wire the coil is made from. This is ordinarily Kanthal, in your chosen “gauge.” In American Wire Gauge (AWG) numbers, a lower number is a thicker, lower-resistance wire, and higher numbers are thinner, higher resistance wires. For most purposes these days, 26 AWG or lower Kanthal is the best thing to build with. Lower gauges produce lower resistances, though, so don’t go below this unless you have a mod that can cope with it. If you want builds over 1 ohm, 28 AWG is better. Other materials (such as nickel) are used for building temperature control coils, but they're harder to work with and aren't recommended for beginners.

- Screwdriver/hex key (to unscrew the post-screws). This is simple. To unscrew the screws on your RDAs posts, you’ll need a matching screwdriver or hex key. Often, RDAs come with appropriate screwdrivers, but a set of precision screwdrivers is a useful addition to any vapers’ arsenal.

- A “guide” for building (screwdriver or drill bit). One challenge when building a coil is to make a coil with a uniform diameter. This means you’ll need a “guide” to work on. A precision screwdriver does this job nicely, but you could also use a drill bit or anything else with a uniformly cylindrical section. Aiming for a 1.5 to 3 mm diameter is a good starting point. The same number of wraps of your coil will give more resistance for a bigger diameter and less resistance for a thinner one.

- Wick material (cotton, silica or other materials). There are many options for wicking materials (which we’ll cover in more detail in a future post – but there’s more info here), but most vapers these days use some form of cotton as a wick. Japanese organic cotton is the industry-standard at the moment. This is purchased in sheets which can be easily cut to size. However, other options like Cotton Bacon (a cotton designed specifically with vaping in mind), cellucotton and even just plain old cotton balls will do.

- Tweezers. Tweezers are vital if you want to make a contact coil – which is what we’ll be doing here. While any tweezers are fine, ceramic-tipped ones have a definite advantage. With metal-tipped tweezers, you can’t touch the coil while pressing the fire button, because it’ll cause a short. With ceramic-tipped ones, this isn’t an issue.

- Wire cutters/scissors. You’ll need some wire cutters or scissors to trim the legs down once your coil is all connected up.

How to Build an RDA Coil

So if you have everything you need, it’s time to get started. Here, we’re going to build a single contact coil (a micro coil), but it’s not very difficult to extend this to multi-coil builds if you get more ambitious in future – just make two coils that are as similar as possible.

Plan Your Coil

This isn’t strictly necessary, but it can be useful. If you have a specific resistance range in mind, the coil wrapping tool on Steam Engine is excellent. Input your wire type, diameter/gauge, the coil’s inner diameter, the length of the “legs” connecting the coil to the posts and your target resistance and it’ll tell you how many wraps to use.

Cut a Section of Wire

Steam Engine will tell you how long the wire should be. However, it’s best to over-estimate since Kanthal is cheap and it’s easier to work with longer strands. I cut mine to around 4 inches a piece, and for your first builds in particular it’s best to cut more. For example, Steam Engine estimates just over two inches of wire for a 1 ohm single coil build with 28 AWG wire and a 2.5 mm inner diameter, but again I’d just cut 4 or even 5 inches to work with and then trim it down to size later.

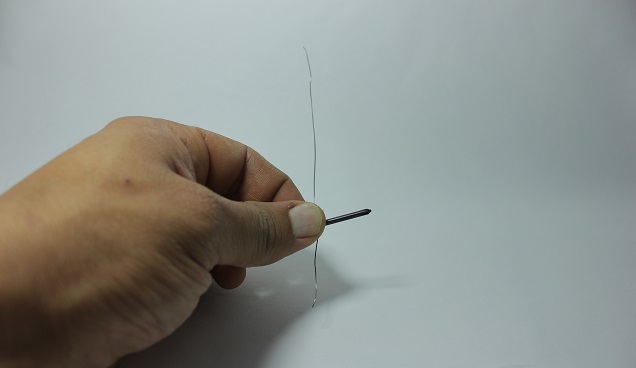

Hold Your Guide Up and Get Ready to Wrap

The best thing to do is start near one end of your wire , leaving around an inch spare. Hold this point up against your guide material, with most of the wire pointing off upwards.

Start Wrapping Your Coil

The aim here is simple: gradually wrap your wire around the guide to form a coil. Since we’re making a contact coil, try to make each successive wrap as close to the previous one as possible without overlapping or crossing wires. This is really the challenging part, unfortunately. The best advice is to keep your wire held taut and wrap the coil with a smooth, consistent motion. It feels a bit like you’re gradually turning a crank. Take your time, though – it’s better to be accurate than to be quick.

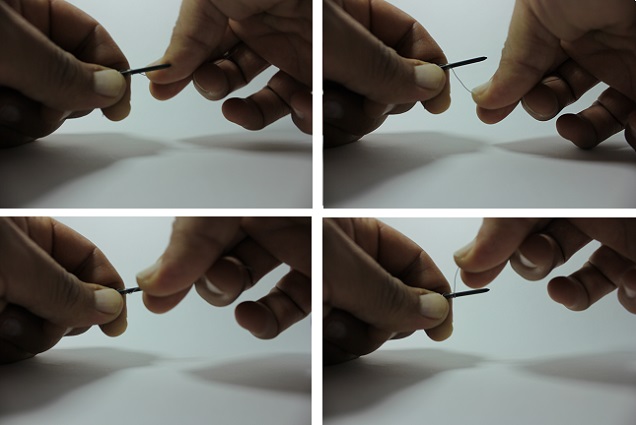

Finish Your Coil on a Suitable Side for Your Atomizer

This depends on your device. On most RDAs, you’ll want both “legs” (the remaining, uncoiled bits of wire) to point in the same direction. However, on some devices they need to point in opposite directions. If you have them pointing in the same direction, you’ll end up with a curious situation in which the coil looks like a certain number of wraps from the top and one less from the bottom. In the example coil from the Steam Engine calculator above, the estimate for “rounded to half wraps” is 6/5. This means it looks like six wraps viewed from the top but five when viewed from the bottom.

I find it helps to wrap your wire a little bit further around the guide than you need to. This means that when you let go and it springs back a little, the leg is roughly in the right place. Ideally, your legs will be slightly different lengths at this stage, but this isn’t essential.

Check Your Coil

Before you get ready to attach the coil, it’s good practice to check that everything is fine. Are the wraps close together without overlapping? If they overlap, you should rectify it however you can. Sometimes you can just adjust it with your fingers or a pair of tweezers. However, most overlaps mean you’ll have to unwind the coil and re-wrap it without overlaps. If your wraps aren’t close enough together, you can probably adjust it with your fingernails, pliers or tweezers. Remember that it doesn’t have to be perfect at this stage – just correct any big errors for now.

This is most of the coil wrapping process done. The only thing remaining is to connect it up and put the finishing touches to it.

Connecting Your Coil

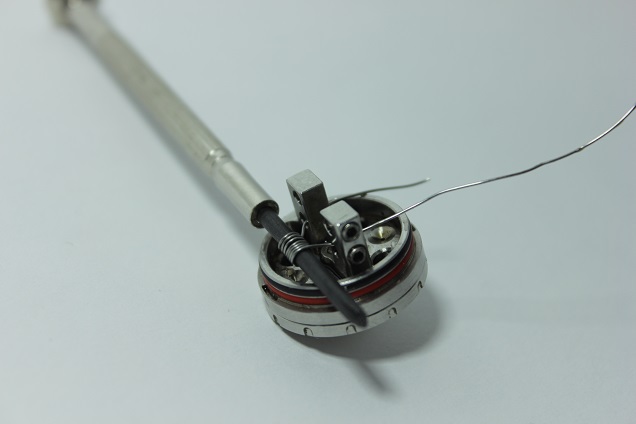

Connecting the coil is really the easy part of the building process. Back in the days when you had to trap the wire-end under a screw-head, this was a bit fiddly. Thankfully, with modern RDAs, all you have to do is loosen the screws in the posts and insert the legs through the post holes. Refer to the relevant section above if you want more information. The upshot is you’ll always want to connect one end up to the center (positive) post and the other up to one of the negative posts. For two-post designs, one leg just goes to each post.

The biggest challenge is positioning your coil right. You want the coil to be close to the posts but not touching them. The best way to do this is to keep your coil on your guide throughout the process. Hold your guide as you feed the legs through the open post holes. This is where having different length legs is useful: then you can thread them through one at a time rather than both at once. Use your guide to position the coil as close to the posts as you can. Once you're happy with the position, tighten down the screws. Make sure the legs are pointing off into the air and not touching the deck, each other or the posts of your RDA – otherwise you could get a short.

Ideally, you’ll want the coil to be slightly higher than where the airflow enters your RDA. On below-coil airflow RDAs, there’s nothing to worry about here, but if your RDA has a slot-style airflow, keeping the coil a bit higher than the slot will improve your performance. You can position it easily using your guide. You can remove your guide when everything is in the right place and tightened down.

Connect your RDA to a regulated mod or use a resistance-checker to see how many ohms it comes in at. This only really matters for mechanical devices, but it’s good practice to check the resistance of your build anyway – most regulated devices have a set range of resistances they’ll work with, so you need to check it’s within them.

If you’re happy, you can trim down the legs as close to the posts as you can.

Finishing Off Your Coil

The last stage to the building process for contact coils is to compress them. This is easily done with the help of a mod and a pair of tweezers. Attach your RDA to your mod with the top cap removed, and then press the fire button to send current through the coils. After a second or two, they’ll start glowing orange-red, and this is when you can adjust them to perfection.

If you have metal-tipped tweezers, release the fire button and then compress the coil from either end using your tweezers. It’s best to almost have your tweezers in position before releasing the fire button, but make sure they aren’t making contact with the coil until you release the fire button. When compressing the coil, you need to be firm enough to make the wraps touch each other but not so much as to deform the coil. The best advice is to start gently and increase the force gradually until the coils press together. Hold the tweezers in position for five to ten seconds as the coil cools. When you let go, the coil should keep its shape.

For ceramic-tipped tweezers, the advice is the same as above but with one key difference. You can make the adjustments while the fire button is held down. This makes this stage much easier, so they’re a good investment if you'll be building a lot.

When you’re happy with the coil, press the fire button again. Ideally, you’ll see an even glow across the coil. On lower powers you should be able to notice it starting from the center and emanating outwards.

Inserting Your Wick

The final stage for building your coil is inserting your wick. This is one part that’s more of an art than a science. The challenge is getting the right thickness on your piece of wick. This is something you’ll get better at with experience. In general, you want the section of wick to be thicker than the inner diameter of your coil. In the picture above, you can see that the wick is about twice as wide as the coil's diameter. However, if it's too thick it will deform your wick as you pull it through. You should also make sure the wick isn’t really densely-packed – fluff it up a little bit before you insert it if it’s really tightly-packed.

However, there is some disagreement on the best approach to wicking. One method in particular (called the Scottish Roll) involves using more wick and having it densely-packed. This passes the point where it would deform your coil if you just pulled it through, so you hold the coil in place with a finger as you do so.

To actually insert the wick, twist one of the ends of your strand into as small a point as possible. This makes it easier to insert through the center of your coil. After this, you can grab it from the other side. Pull it through so your wick is reasonably evenly spread across both sides of the coil. You may have to hold the coil in place as you do this if you’ve used a denser wick.

Trim Your Wick, Drip and Vape

Then when it’s in place, you just have to trim it down and you’re ready to vape. The aim is to cut the wick so both ends just reach the bottom of the juice well. You can estimate this by comparing the length of your wick with the outside of the deck on your RDA. Cut it so it reaches the bottom of the deck and you should have about the right amount. At this point, you might have a neat edge, so it helps to fluff it up a little. You can do this by poking the middle of the wick with closed tweezers and then letting them open up to spread the wick.

Use a screwdriver or pair of tweezers to poke the ends of the wick down into the juice well. Now all you have to do is drip juice on the wick and you’re ready to vape. Drip enough to soak the wicks, but you can go further and completely fill your juice well if you like. At this point I always hit the fire button and triumphantly watch the vapor rise up from my new coil. Admittedly, though, this is completely and utterly useless.

Conclusion: RDAs Aren’t So Scary

Hopefully this post has shown you that rebuilding really isn’t so bad. It's one of the most technical things you'll have to do as a vaper, but you'll quickly get the hang of it. Half-hour or even hour-long building sessions when I was getting started are now five to ten minute jobs, and the results keep on improving. Not only will you get better performance, you’ll also save tons of money by rebuilding. Don’t get disheartened if you struggle at first: you’ll be making excellent coils in no time if you keep practicing and experimenting.